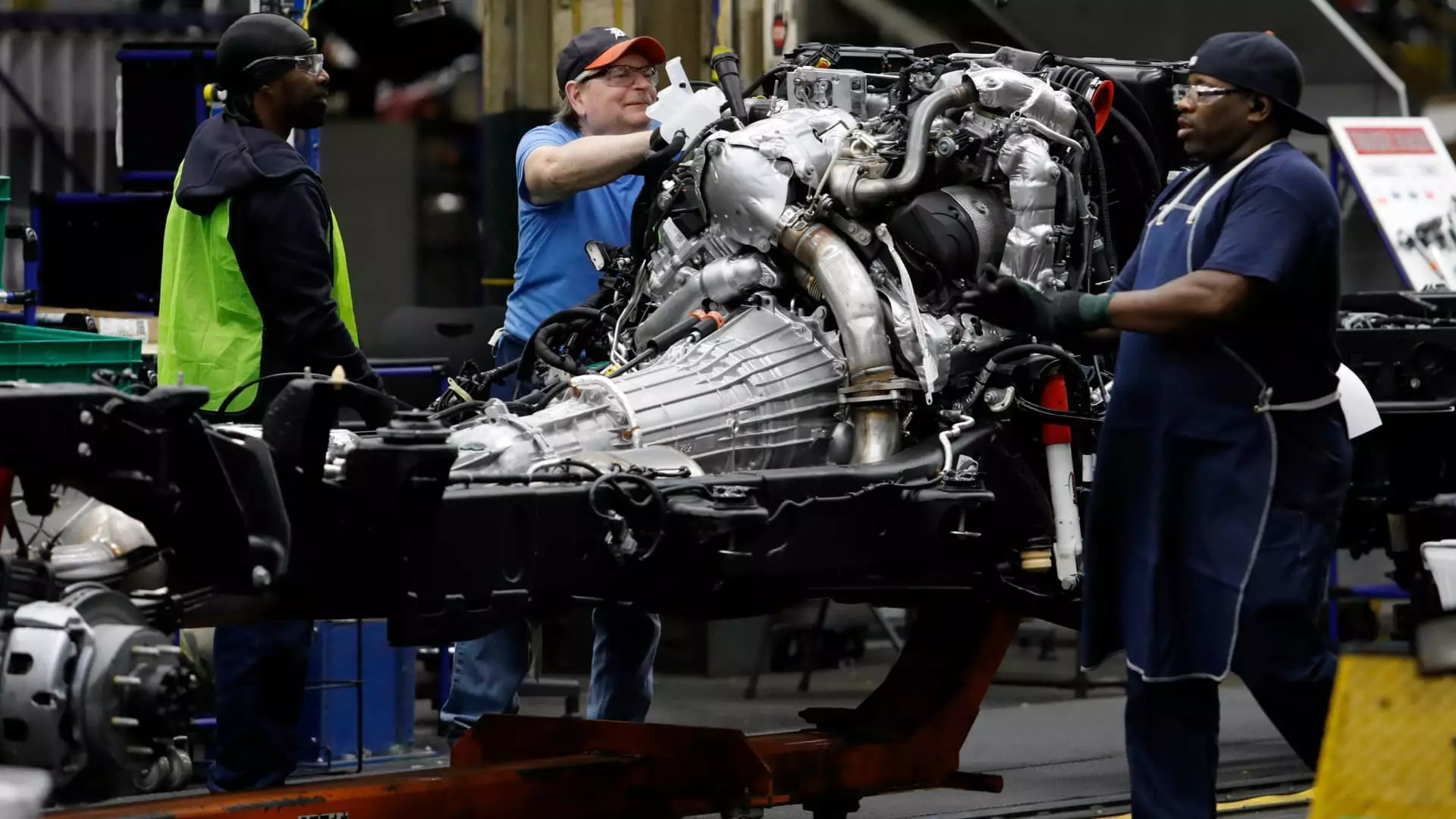

Natural disasters can have profound effects on industries dependent on complex supply chains, and the recent case of Hurricane Helene striking the southeastern United States illustrates this phenomenon vividly. General Motors (GM), a stalwart in the automotive industry, faced operational interruptions due to supplier challenges attributed to the hurricane. The closure of production for large pickups and SUVs at two pivotal plants in Flint, Michigan, and Arlington, Texas, signifies the ripple effects of environmental disasters on corporate operations and the broader economy.

GM’s decision to halt operations at the Flint and Arlington plants, notable for producing heavy-duty trucks and full-size SUVs, respectively, underscores how external events can derail production schedules. The specific cancellation of shifts reflects an urgent response to supply chain vulnerabilities exposed by Hurricane Helene, which made its presence felt after making landfall in Florida. GM’s spokesperson, while refraining from providing a timeline for the resumption of production, did indicate that the Arlington facility could potentially restart operations soon, indicating a need for rapid recovery amidst uncertain circumstances.

In an emailed statement, GM articulated its commitment to working closely with affected suppliers to navigate these disruptions effectively. This collaboration is essential not only for the automobile manufacturing giant but also for the livelihoods of the suppliers’ employees and their local communities. The hurricane’s devastation has raised concerns, especially with reports of significant loss of life and many individuals still unaccounted for, stressing the human aspect behind corporate decisions.

Jeffrey Morrison, GM vice president of global purchasing and supply chain, has emphasized that the operational disruptions faced by the company—stemming from the pandemic and now exacerbated by the hurricane—have prompted a reevaluation of GM’s supply chain strategies. The pandemic served as a crucial learning opportunity for the automaker, compelling it to gain a deeper understanding of its supply chain’s intricate web. Morrison’s insights reveal that their enhanced visibility into sub-tier suppliers has been pivotal in navigating recent challenges, leading to improved resilience against unexpected disruptions.

As GM continues addressing the current setbacks, the juxtaposition of crisis and opportunity is evident. The recent strike by port workers, also highlighted by Morrison, ended in time for dockworkers to return, suggesting that GM navigated yet another layer of logistical complexity. By actively strengthening supplier relationships and refining supply chain management practices, GM is not only aiming to recuperate but also to fortify its operations against future adversities.

The operational halts at GM serve as a stark reminder of the unpredictable nature of both natural and economic challenges. However, with a concerted effort to engage with suppliers and a commitment to learning from past disruptions, GM is charting a course for recovery and resilience. As the automotive industry increasingly grapples with global uncertainties, the reflections from these events may shape the future operational strategies of not just GM, but the entire sector in times of adversity.